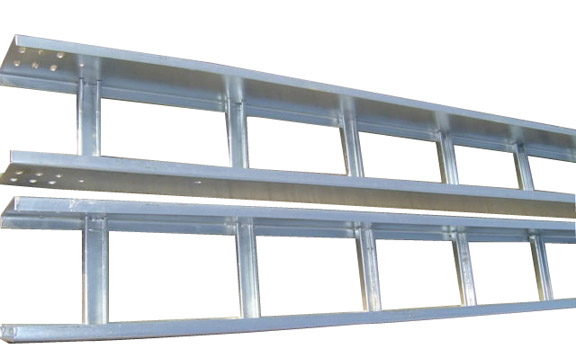

关于电缆桥架修复和维护的方法

电子工业是国民经济支柱工业之一,也是新式科学技术开展工业。电缆的防护就会显得特别重要,运用济南电缆桥架能够起到电缆防尘防腐等损伤电缆运用寿命的状况呈现。下面整合了关于电缆桥架怎么修复和维护的方法,得当的维护可以延长电缆桥架的使用寿命。

The electronic industry is one of the pillar industries of the national economy, and it is also a new type of scientific and technological development industry. The protection of cables will be particularly important. The use of cable tray in Jinan can play a role in the situation of cable dust prevention, corrosion prevention and other damage to the service life of cables. The methods of repair and maintenance of cable tray are integrated below. Proper maintenance can extend the service life of cable tray.

电缆桥架修复:

Repair of cable tray:

1.锈迹处理

1. Rust treatment

通常电缆桥架采用氯磺化底漆二道进行两部分除锈,表面除锈处理质量直接影响防腐工程的寿命,现场除锈通常是砂轮机或者人工除锈,在表面处理之后,在4小时内涂上底漆。如果处理不当发现有新锈,必需进行重新处理。

Generally, cable tray is subject to two parts of rust removal with two layers of chlorosulfonated primer. The quality of surface rust removal treatment directly affects the service life of the anti-corrosion project. The on-site rust removal is usually performed with a grinder or manually. After surface treatment, the primer is applied within 4 hours. If new rust is found due to improper handling, it must be re treated.

2.涂层处理

2. Coating treatment

涂层工艺分为刷涂、滚涂。刷涂或者滚涂时每层应从横交错反复进行涂,直到均匀为止,不能出现漏涂。

The coating process is divided into brush coating and roller coating. When brushing or rolling, each layer should be applied repeatedly in a horizontal and staggered manner until uniform, and there should be no leakage.

3.施工环境要求

3. Construction environment requirements

环境需要通风良好,温度好在13℃-30℃,不得低于5℃,相对湿度保持在80%以内。不宜在强烈日光下施工。遇到雨、雾、强风气候不得在室外进行施工。

The environment needs to be well ventilated, with a temperature of between 13 ℃ and 30 ℃, not less than 5 ℃, and a relative humidity of within 80%. Construction should not be carried out in strong sunlight. Construction shall not be carried out outdoors in rainy, foggy, or windy climates.

电缆桥架维护:

Cable tray maintenance:

1.避免摆放在高温潮湿地方。

1. Avoid placing in hot and humid areas.

2.避免与腐蚀性液体接触。

2. Avoid contact with corrosive liquids.

3.可用电缆桥架专用的保养蜡进行保养。

3. Special maintenance wax for cable tray can be used for maintenance.

4.定期清理电缆桥架表面的灰尘与锈迹。

4. Regularly clean the dust and rust on the surface of cable tray.

此外在运输、装卸电缆桥架时,电缆桥架架应牢固地系在车辆上,以免碰撞和损坏电缆桥架。卸货时,电缆桥架架不得直接从车上推下,搬运时注意避免碰撞;存放时,必须分门别类堆放,不得敲击。这些层应该用软物体分开。

In addition, during the transportation, loading and unloading of cable tray, the cable tray frame shall be firmly tied to the vehicle to avoid collision and damage to cable tray. When unloading, the cable tray frame shall not be pushed down directly from the vehicle, and collision shall be avoided during handling; When storing, they must be stacked in different categories and must not be knocked. These layers should be separated by soft objects.

请勿在电缆桥架上放置重物,以免超重的电缆桥架架变形或损坏防腐层。在潮湿或腐蚀性环境中,应采取相应措施,如有损坏应立即处理;镀锌电缆盘验收后应放置在干净干燥的地方,并用盖板覆盖,避免酸、碱等腐蚀性物质。

Do not place heavy objects on the cable tray to avoid deformation or damage to the anti-corrosion coating of the overweight cable tray. In humid or corrosive environments, corresponding measures should be taken, and any damage should be dealt with immediately; After acceptance, the galvanized cable reel should be placed in a clean and dry place and covered with a cover plate to avoid corrosive substances such as acid and alkali.

更换桥架前,应召开会议,讨论制定一套严格的措施和施工方案,并经电机部门审查。审核结束后,准备好各种工具和材料,分配人员,安排好每个人员的具体职责。开工前,到施工现场进行实地勘察,确定需要更换的桥架,制定表格,做好详细记录。更多相关内容就来我们网站http://www.sdhangfeng.com咨询吧!

Before replacing the bridge, a meeting should be held to discuss and develop a strict set of safety measures and construction plans, which should be reviewed by the motor department. After the audit, prepare various tools and materials, assign personnel, and arrange the specific responsibilities of each person. Before starting work, conduct on-site investigation at the construction site to determine the bridge that needs to be replaced, develop a table, and make detailed records. For more related content, come to our website http://www.sdhangfeng.com Consult!